|

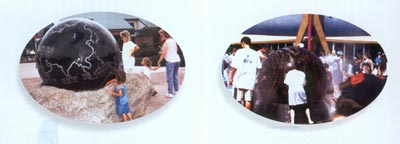

Gigantic

granite spheres floating and rotating on a

thin film of water are catching the

imagination of people all over the world.

Ben Smalley reports on the art and

science of floating ball fountains.

From Disneyland in America to shopping

centres and public parks in Europe,

there are an increasing number of

locations where floating ball fountains

are being installed to catch the eye of

the public and inspire their

imagination.

The novel attractions have become a major

talking point as people try to fathom out

how a massive stone ball weighing up to 45

tonnes can float on a thin film of water

and rotate so easily that even a small

child can change their direction.

The concept of the fountains was conceived

by the head of a stone company in Finland,

who used a period of recession in the

global construction industry several years

ago to develop an idea he had been

pondering for a lifetime.

Eero Vainikka, Managing Director of

Sorvikivi Oy, one of just a handful of

companies now making the fountains

worldwide, developed the first ball

fountain for an installation in Berlin,

and now millions of passers-by can admire

the highly polished, five-tonne red

granite ball as it revolves majestically

on a wafer-thin film of water in the city

centre.

Since then, the company has received

similar requests for its fountains from

Italy, China, Singapore and the USA, and

is now actively targeting the Middle East

market.

Vainikka says the company hopes to produce

around half a dozen massive stone ball

fountains a year, in addition to many

smaller, and even table-sized, versions.

“We want our fountains to give pleasure in

towns and cities around the world,” he

says. “Because flowing water and beautiful

Finnish stone make a really attractive

combination.”

He says the secret to the company’s

success is its ability to grind and polish

stone to an accuracy of a few hundredths

of a millimetre – making it one of only a

handful of companies in the world able to

do this.

“A tolerance of 4-8 hundredths of a

millimetre is enough to make a revolving

stone fountain work,” he says. “But the

more accurate the dimensions, the thinner

the amount of water needed.”

For example, the large five-tonne stone

delivered to Berlin is made to revolve

using 13 litres of water a minute, and the

water film between the ball and its

pedestal is only one to two tenths of a

millimetre thick.

Besides being dimensionally accurate, a

revolving stone ball must also be highly

balanced, and it can take Sorvikivi Oy at

least two months to shape and polish a

large stone out of Finnish granite, while

accurate balancing can require several

more days.

“Although the basic work takes place on

computer controlled machines, finishing is

always done by hand as it takes an

experienced eye to bring out the stone’s

inner character,” Vainikka says.

Kristian Lobbas, who acts as a consultant

for the Finnish company in Dubai, says the

fountains have great potential in the UAE

due to the amount of high profile

construction projects taking place.

“I have shown them to many people here and

I think there are quite a few projects

where they could be included as a theme,

such as on roundabouts or in theme parks,

as a reminder or monument of an important

global meeting, not to speak about a

landmark for an international hotel

chain,” he says. “But how they are

incorporated into an architectural

surrounding – so the fountain forms one of

the attractions within a feature – is up

to the architect or designer, and how much

imagination he or she has.”

Lobbas, who has worked in the quarrying,

stone and mineral industries in the Middle

East since 1986, says the fountains appeal

to different people for different reasons.

“For me, the attraction is the technical

aspect and the beauty - with the light and

rotation, the texture and reflections of a

colourful granite ball change all the

time.” he says. “But their primary

attraction for most people is as an

architectural feature and curiosity - even

if the balls weigh between 10 and 45

tonnes, they rotate so easily that even a

child can move them.”

The fountains consist of the main polished

sphere and a pedestal which acts like a

ball bearing housing. Basic scientific

principles mean the ball will rotate

freely and continuously when water is

pumped in from underneath, so long as the

sphere is perfectly round and balanced.

The balls can also rotate using air,

instead of water.

“It’s essentially a hydraulic principle,”

Lobbas explains. “The water comes in

through a small pipe and divides itself

evenly across a large area, and the

pressure in a liquid or air divides itself

equally all over the surface so you don’t

need a large pressure.

“Two other principles are also at work:

The surface tension of water is quite high

– that is why insects and some other

animals can run on water – which makes the

surface quite hard to break. In addition,

once the film of water lifts up the ball,

the small, directed friction caused by the

running liquid or air makes the ball

easily rotate by itself in a desired way

so long as water or air is being pumped

underneath. Even rotations in different

directions can be created

“The ball has to be both a perfect sphere

and in perfect three-dimensional balance

with the weight divided equally in order

for it to work: You can tell how well the

ball has been made by just looking at the

amount of water it needs to float and

rotate – the better it is done, the less

water it needs.”

The Finnish company has made ball

fountains of varying diameters – from

small balls or groups of them, but are

today concentrating mainly on spheres with

a diameter from 60 cm to several metres -

but the cost increases sharply as the size

increases.

“The problem is not so much the

manufacturing, the difficult part is

finding a three dimensionally balanced,

homogeneous block of stone of the

appropriate size which has no cracks or

other flaws in it,” Lobbas explains.

“The biggest sphere we are currently able

to make has a diameter of 3.2 metres, but

we have yet to find a customer for it.”

|